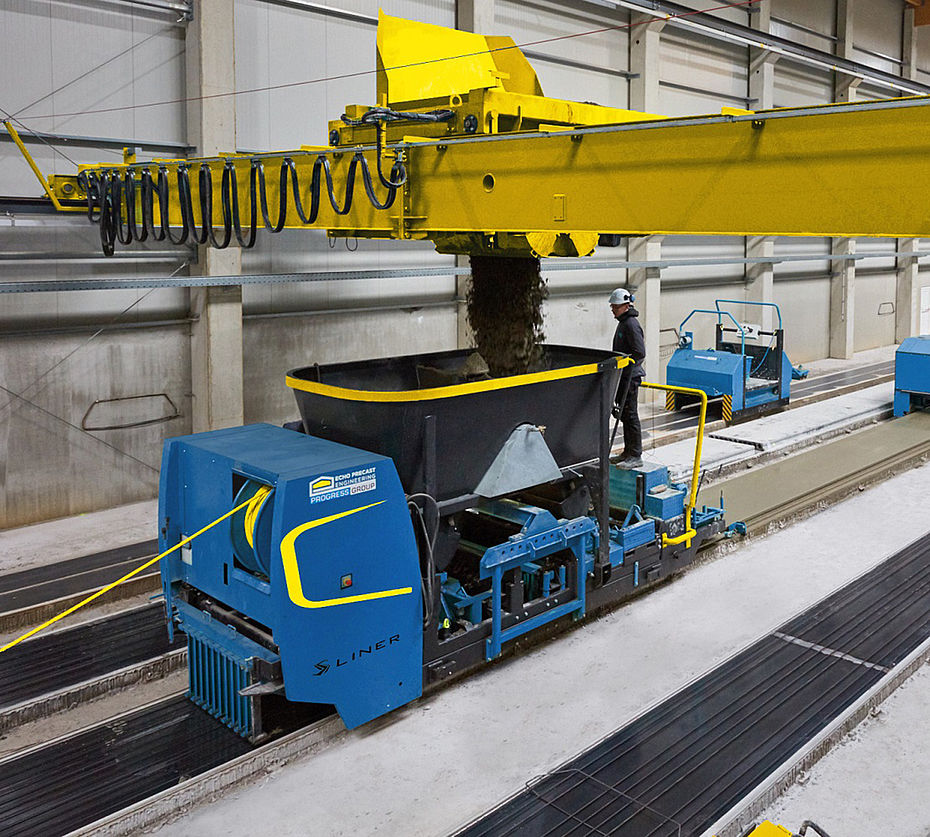

Concrete delivery system

The concrete delivery system with bridge is designed for the automatic supply of fresh concrete from the batching plant to a casting machine (Extruder and/or Slipformer). A flying bucket transports the concrete either via a rack or from a fixed silo to the point where concreting is required.

Cycle times, line bucket sizes or the bed for the line bucket are designed to customer specifications and adjusted to the function of the casting machine (Extruder and/or Slipformer) and to the finished parts to be produced and the rate of production. The system is constructed in such a way that the concreting process on the beds does not have to be interrupted because of a lack of fresh concrete.

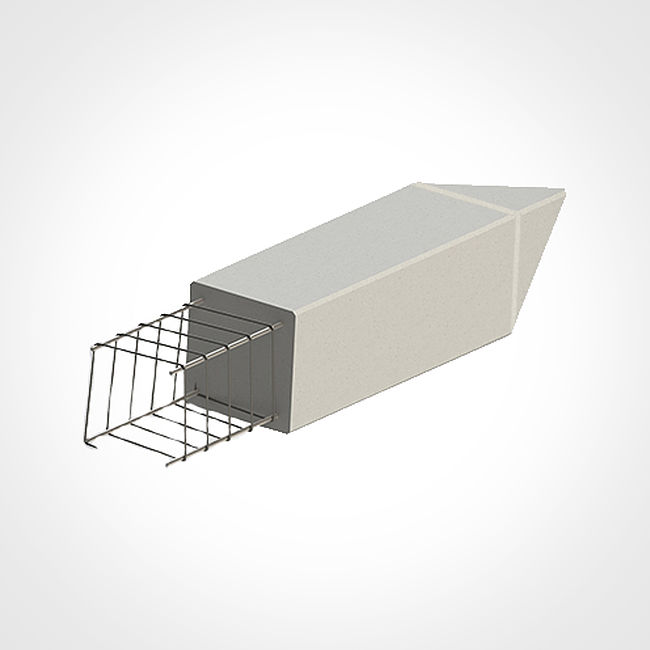

In principle, the concrete delivery system is comprised of a Line supply with a Line bucket with a capacity of 1.5 m³, 2.0 m³ or 2.5 m³, a bridge and tracks. Since the bridge is PLC controlled, it can run fully automatically or be remote-controlled by a member of staff. The concrete delivery system is configured for fast transport of the concrete by a flying bucket on a two-rail system from the mixer system to an intermediate silo or a casting machine. The concrete transport system is suitable for straight and curved routes.

Line supply Semi-portal or Bridge possible

Customised solutions

Automatic and manual operation