Automatic plotter SmartJet

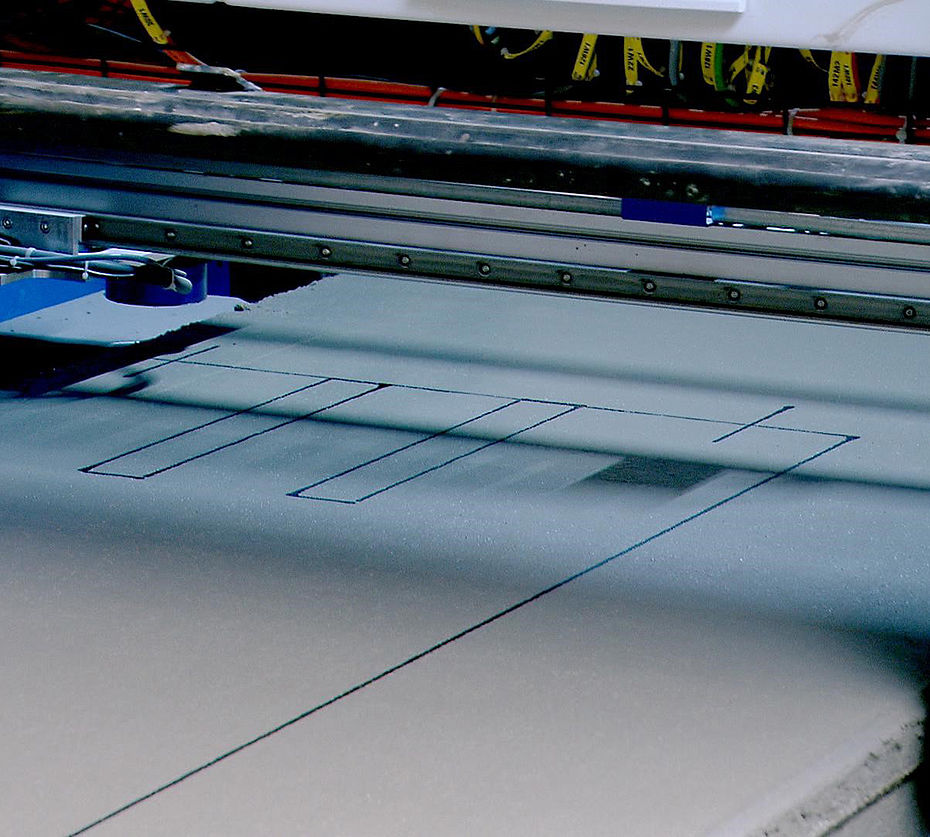

With the Automatic Plotter SmartJet it is possible to draw and print data such as cutting angles, project identifications and areas to be cut-out on the precast concrete elements. Prints can be made on top of the element as well as on both sides. This prepares the slabs for the next operating processes with a concrete aspirator or a concrete saw.

The plotter prints geometric shapes and text on the concrete elements prior to cutting. This includes cutting lines (straight across the element or at an angle), markings for cut-outs, the position of drainage holes, etc. The texts are mainly identification numbers for elements, projects or customer data for the identification of the finished slabs. Since the automatic plotter is battery-powered, no cabling is needed for production.

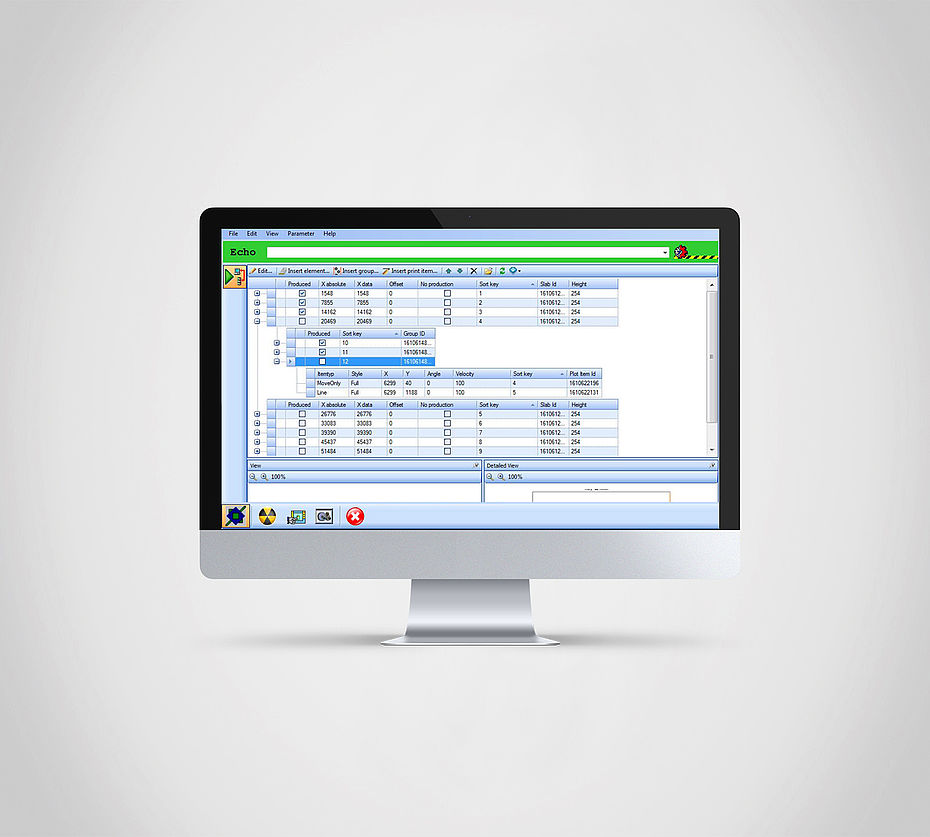

The machine is equipped with an industrial PC. The data is transferred to the plotter as a PXML file, for example by using a USB storage medium or wireless network connection. Data are monitored prior to printing by a special type of software. PXML stands for Progress XML and is an innovative concept for open data transfer for precast concrete element manufacturers and rebar shops, developed by the Progress Group (www.pxml.eu). The software to generate the PXML files can also be supplied.

The new generation of the plotter SmartJet perfectly represents the Industry 4.0. It can synchronize its work with the production of the Slipformer S-Liner® or Extruder X-Liner®. The SmartJet consistently follows the production machine at 2 meters distance and prints marks without error. It can also be optionally equipped with special ink to make marks for "Line detection". This allows the fully Automatic Multi-Angle Sawing Machine MAS to detect the lines where it should make straight or angled cuts as required.

Fully automatic

Data transfer via USB or W-LAN

Laser positioning

Features

| Smart Connected |

|

| High efficiency |

|

| Reliability |

|

| Best accuracy |

|

| Flexibility |

|

| It is possible to print: |

|

Special Options

- Wheep hole drilling with “air blow”

- Special Ink for “line detection”

Technical Data

Dimensions:

Weight | 1250 kg (battery included) |

Height | 1720 mm |

Width | 1690 mm |

Length | 2490 mm |

Speed:

Maximum speed | 18 m/min |

Average production speed | 10 m/min (Depending on the amount of data) |

Electrical Data:

Operating voltages | 48 VDC (battery) |

Battery charger | 230 VAC |

Battery | 48 VDC |

8 hour battery life.10 hour charging time (from depleted condition) | |

* Information set for a standard 1.2 plotter

Product Specifications

- Each machine type can be configured for a track width of 1.2 m, 1.5 m or 2.4 m.

- Positioning is by means of wheel decoder and laser, with collision detection

- Printing head lowers automatically to working position on different slots sizes

- Plotter can work on any slab height from 6 cm to 50 cm

- Touch screen interface. Graphic overview of the bed layout lines shown on screen

- PXML stands for Progress XML and is an innovative concept for open data transfer for precast concrete element manufacturers and rebar shops, developed by the Progress Group.

- The software to generate the PXML files can also be supplied.

- Files loaded via USB port or wirelessly

- Internal memory capacity – 40 GB (expandable)

- Since the automatic Smartjet is battery-powered, it can run without a cable.

- Plotter is not recommended for outdoors operations, but can be used outside under favorable weather conditions (no rain, no freezing temperatures)

- Remote troubleshooting