MD Beton: Automation to better serve demanding customers

MD Beton of Mouscron, Belgium, is a family-owned company specialized in the production of precast prestressed concrete elements. The company is known for putting customers needs first and developing products tailored to the requirements of the clients and their construction projects. That is why, in 2019, it identified an opportunity in the market and extended its offer with 2.4 wide hollow core slabs. The demand for these unique slabs made with Echo Precast Engineering machinery has been increasing in the last year, so the company has decided to invest in automation in order to meet its commitment to deliver high quality products in a short time.

Why automate the marking of the slabs?

Because it allows a job to be done faster and more accurately with less manpower.

Maarten Desplenter, Technical and Production Manager at MD Beton says

„We decided to invest in a plotter to encrease the automation of the production process. Beforehand, we needed one person 100% dedicated to marking the slabs. Now, this person can also support other areas of production.”

”Automation additionally reduces mistakes considerably. Previously, production drawings were done one by one, but now everything is digitally designed and ordered and sent to the machine within seconds.“

"Printing the logo is a good form of advertising, we put it on the edges. Thus, they can be seen on streets and roads during transport and installation at the construction site".

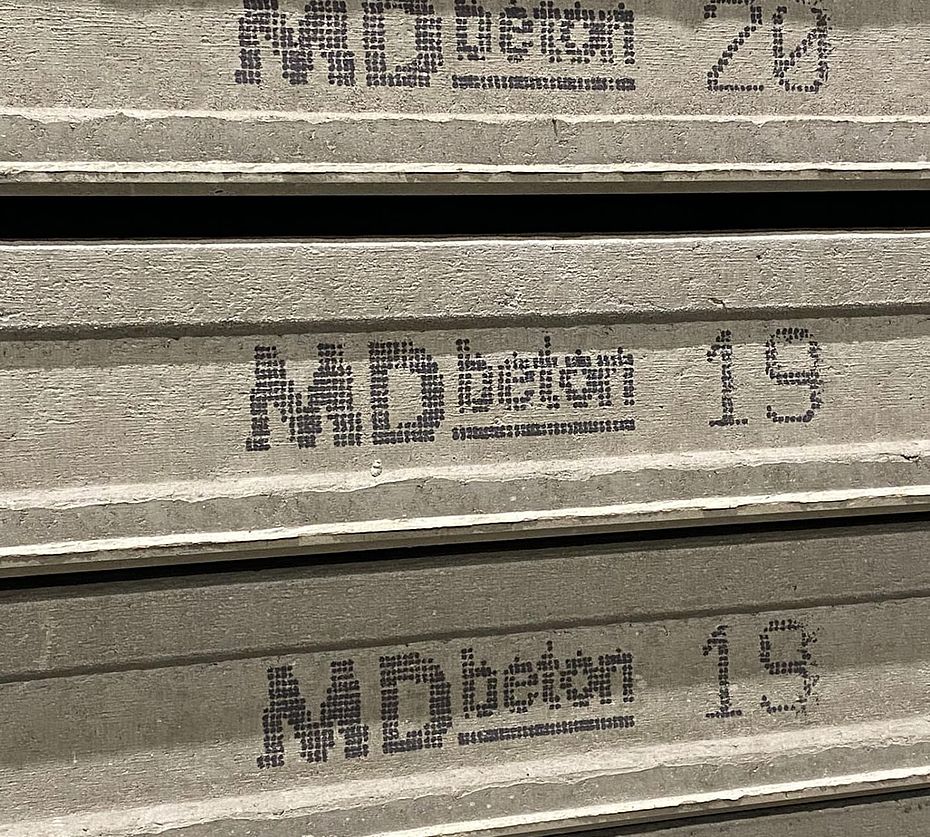

Flexible marking and weep holes with Automatic SmartJet® plotter

The plotter can do top and both sides printing. It can do all kinds of geometric lines, numbers and letters and even print company logos.

MD Beton's SmartJet® is also equipped with a system for drilling weep holes with the air blow special option. It works as follows: the drill drills from the top to the bottom. Afterwards, the air blow system shoots pressurized air to clear concrete from the bottom perforation to prevent it from closing with the fresh concrete around it. Typically, there is made one weep hole for each core of the slab. This procedure can facilitate the drainage of the slabs in case they get wet from rain or other agents during stockpiling or moving to the job site.

We have improved our speed and accuracy and are happy to recommend this machine to any slab producer who is looking to automate their plant

Maarten Desplenter, as Technical and Production Manager at MD Beton